What is flexo printing? How is this printing technique different from offset printing? Is the quality of products printed using flexo printing technique good? Please join us to find out details in the article below.

What is flexo printing?

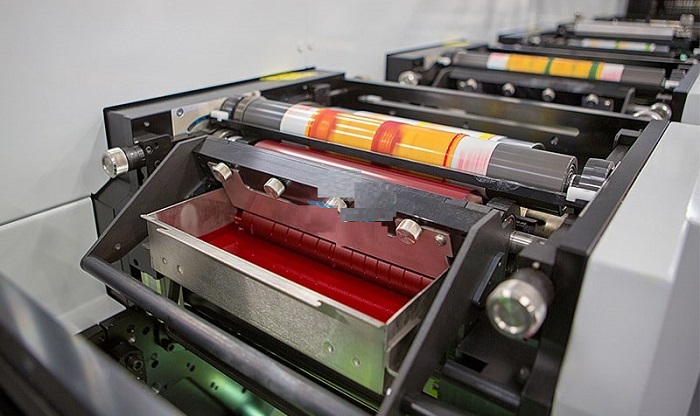

Flexo printing (also known as flexography) is a technique of embossing information such as images, text, decorative motifs… This information on the printed mold will be located higher than the unprinted details. When printing, all images on the mold will be in the opposite direction compared to the anilox axis. Ink for printing products will be supplied to the mold through the anilox shaft.

Flexo printing technique with embossed information gives the viewer a more realistic and vivid feeling than other printing techniques, creating an impression on customers and consumers.

Products that are often printed using flexo printing technology include: printing cartons, printing labels, printing flyers, stickers or product labels…

Operating principle of flexo printing technique

For flexo printing technique, ink will be supplied to the anilox shaft by dipping directly into the ink. The ink goes through small cells on the surface of the anilox shaft to get inside. The remaining ink on the surface will be wiped off with an ink knife.

The mold for flexo printing is usually made of photopolymer plastic. The printing mold will come into contact with the surface of the anilox shaft, take ink from small cells on the surface of the shaft and then transfer it to the surface to be printed to create the final product.

What is offset printing?

Offset printing is a printing technique that uses pressure applied to offset plates (made of rubber) to print information, images, and patterns that have been inked and pre-printed onto the material surface. previous offset plate. This printing technique helps minimize water absorption of the printed paper, giving the best printing quality.

Offset printing can be used to print on different types of materials such as paper, wood, metal… commonly used to print paper packaging.

Compare flexo printing and offset printing in the printing industry

With the above information, readers have grasped what flexo printing technique is and what offset printing is. Through the above information, in the next step, let’s compare flexo printing and offset printing to know more about the advantages and disadvantages of both printing techniques.

Advantages, disadvantages and applications of flexo printing technique

Máy in flexo cuộn với chiều dài đa dạng

Flexo printing technique possesses outstanding advantages when printing goods and products. However, certain disadvantages still exist.

Advantages of flexo printing technique

- The ink dries quickly, colors and details do not smudge or smudge

- Ink adhesion when printing flexo is very good

- Printing costs are cheap, cheaper than offset printing

- Can be used to print on many different types of materials and print in very large quantities.

Disadvantages of flexo printing technique

- This printing technique is quite time-consuming for creating prints

- The cost of printing molds is quite high

- Only suitable for very large printing orders

Application of flexo printing

Printing using flexo technique is suitable for industries producing nylon packaging, paper packaging, printing paper cups… In addition, the printing technique can also be applied to print on fabric and plastic materials. for good image quality.

Advantages, disadvantages and applications of offset printing technique

It is a modern printing technique with many outstanding advantages and is used in most printing establishments. However, offset printing still has certain disadvantages.

Advantages of offset printing technique

- Offset printing technique provides sharp, detailed image quality. The product is cleaner than flexo printing.

- Making prints is easier and less time consuming

- Prints last longer thanks to a printing process that does not come into contact with water

- Can be used to print on many different types of materials, including uneven surfaces.

Disadvantages of offset printing technique

- Offset printing technique is quite complicated. To create the final product, it needs to go through many different stages, so it is not suitable for printing for small quantity orders. If printing in small quantities, the cost per product is very high.

- The color of the product when printed using offset technology may be distorted

Application of offset printing

Offset printing technique is often used to print paper packaging, paper bags, boxes, paper, cartons, advertising publications or product labels…

Thus, inbaobigiay.vn article together with readers learn about what flexo printing is, compare flexo printing and offset printing, what are the advantages and disadvantages, and know the applications of each printing technique. Hopefully, the above information will be useful and help readers make easier choices when they need to print products.